Prebuilt German Kitchens: Precision, Quality and Innovation

German kitchens have a longstanding reputation for precision engineering, exceptional build quality and thoughtful design. Manufactured with advanced technology and meticulous attention to detail, they offer durability, consistency and functionality that small local workshops cannot usually match.

Surface finishes and UV protection

One of the lesser-known advantages of German kitchens is the quality of their door finishes. Most German laminate and lacquered doors undergo UV-curing processes, where multiple layers of lacquer are hardened under ultraviolet light. This creates an extremely hard, colour-stable surface that resists fading, yellowing and general wear, even in bright or sun-exposed rooms.

In contrast, many small English manufacturers use basic melamine or foil-wrapped doors without dedicated UV protection. These surfaces can fade or become patchy over time, especially in white or lighter colours. German doors retain their finish for years because UV protection is engineered into the material from the start.

Quality materials and carcase construction

German kitchens typically use high-density engineered boards and components designed to last for decades. Many units are factory-assembled as rigid, glued and dowelled carcases, meaning each cabinet is already solid and stable long before the back panel is fitted.

This construction method is fundamentally different from English-style cabinets, which often rely on a solid 18mm backboard for strength. Local manufacturers frequently claim that thinner backs, like those used in German systems, will bow or bend over time. That is only true in cabinets where the back is being used as a structural support.

In a German carcase, the back panel is not structural. The strength comes from the engineered frame itself: 19mm structural cross beams, precision-machined joints and a rigid, dowelled structure that does not need the backboard to hold its shape. The thinner flexi back panel is used purely for enclosure, not stability.

Because the rigidity is built into the carcase, the unit remains perfectly square and stable even if the back panel is removed entirely. Once the thinner panel is fitted into the already-rigid frame, the cabinet becomes exceptionally strong: far stronger than a handmade cabinet that depends on a thick back to stay upright.

This is why German kitchens can be transported worldwide, stored in bulk, fitted in homes across all climates and still retain perfect alignment. Their durability comes from engineering, not from the thickness of a single board.

Advanced edging and moisture resistance

Edges are one of the first places cheaper kitchens fail. German manufacturers use high-performance edging systems such as PUR or laser/zero-joint edging, which form a seamless, sealed bond that protects against steam, heat and moisture.

This matters in everyday life. Areas around sinks, dishwashers, boiling-water taps and kettles can quickly cause swelling, peeling or splitting in basic EVA or iron-on edging. German zero-joint edges maintain a tight, clean finish for years.

Precision engineering and robotics

German kitchen production is heavily automated. CNC machines and industrial robots cut, drill and assemble components with exceptional accuracy, ensuring every hinge hole, fixing point and joint aligns perfectly across thousands of units.

Manufacturers routinely use robotic test rigs to simulate decades of use. Doors and drawers are opened and closed thousands of times to confirm long-term reliability. This level of controlled testing is simply not possible in a small manual workshop.

Safety, tilt protection and fixing systems

German systems are designed with safety in mind. Tall units and wall cabinets are supplied with engineered anti-tilt brackets, reinforced wall fixings and precision mounting rails to prevent tipping or accidental unhooking. These safety features are especially important in kitchens with tall larders, heavy internal pull-outs or young children.

Intelligent storage and ergonomics

German kitchens place a strong emphasis on everyday practicality. Full-extension drawers, soft-close runners, organised larders, clever corner solutions and well-designed internal storage come as standard. Everything works as one integrated system, making daily use smoother and more efficient.

Longevity, durability and global performance

Large German manufacturers produce thousands of kitchens daily, all shipped worldwide. These same cabinets must withstand freezing Canadian winters at –20°C and humid +45°C conditions in places like Dubai. Because manufacturers cannot redesign their product for each climate, the entire system is engineered to perform consistently anywhere.

This global performance is a clear indication of the long-term reliability you can expect in a typical British home.

Quality control and guarantees

German factories maintain strict quality control at every stage: board selection, edging, drilling, assembly, finishing and packing. Because quality is built into the process, many brands offer guarantees of 20 years or more. Their investment in R&D, robotics and endurance testing gives them the confidence to stand behind their kitchens long term.

Customisation within a modular system

German kitchens are modular, but far from limited. With hundreds of cabinet sizes, heights, depths and internal variations — along with a wide choice of colours and finishes — they offer extensive flexibility while preserving the precision of factory-built construction. Bespoke items are possible but may increase cost if they sit outside the standard production system.

German Kitchens vs Bespoke Kitchens from Small Local Manufacturers

Bespoke kitchens from small English workshops offer freedom of layout and sizing, but there are important differences to consider.

Inconsistent quality control

Local workshops rely heavily on manual cutting, edging and drilling. Quality can vary depending on the tools, the operator and the conditions on the day. There is rarely the same level of monitored testing or documented long-term performance.

Material choices and edging

To remain price-competitive, many small manufacturers use cheaper boards and basic edging methods. These can look acceptable initially but often deteriorate faster in humid or high-heat areas, leading to swelling, peeling or moisture damage.

Lack of independent endorsement

Small workshops generally buy MFC sheets, cut them down and edge them manually. This process is not typically certified or endorsed by recognised UK or European bodies. In contrast, German manufacturers design, test and certify complete kitchen systems — not just individual parts assembled on the day.

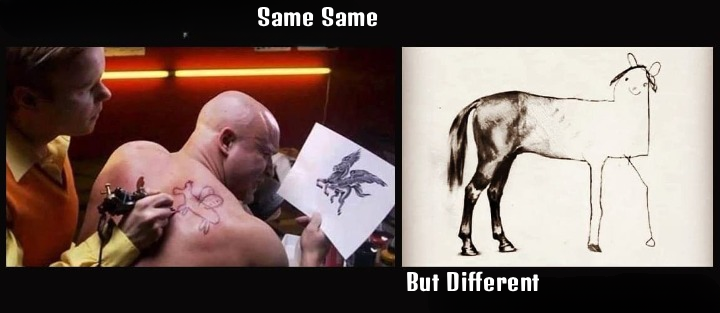

The “German Parts = German Kitchen” Misconception

A growing number of small manufacturers claim their kitchens are “the same as German kitchens” because they use a few German components, usually hinges or occasional drawer runners. But a kitchen’s quality is not defined by one or two imported parts. It comes from the entire system: the density of the boards, the engineered joints, the edging, the legs that support the weight, the runners that carry heavy drawers, the precision of the drilling and the rigidity of the carcase.

Fitting a German hinge onto a manually assembled, lower-grade British carcase does not suddenly make the whole kitchen “German quality.” If the edging, substrate materials, legs, runners and construction method are cheaper or inconsistent, the overall performance will always fall short, regardless of how premium that single component is.

It’s like your local mechanic buying a few high-end parts and attempting to build a Mercedes or BMW himself. The parts may be genuine, but the finished product is not the same — not in engineering, not in testing, and not in reliability.

A true German kitchen is a fully designed and precision-engineered system, not a collection of isolated components.